Future Trends in Manufacturing Technology Adoption

The landscape of manufacturing is undergoing a profound transformation, driven by rapid advancements in technology. Industries worldwide are exploring and integrating innovative solutions to enhance productivity, streamline operations, and maintain a competitive edge. Understanding these emerging trends is crucial for businesses aiming to adapt to evolving market demands, optimize their processes, and foster sustainable growth in a dynamic global economy. This article delves into the key technological shifts poised to redefine manufacturing in the coming years.

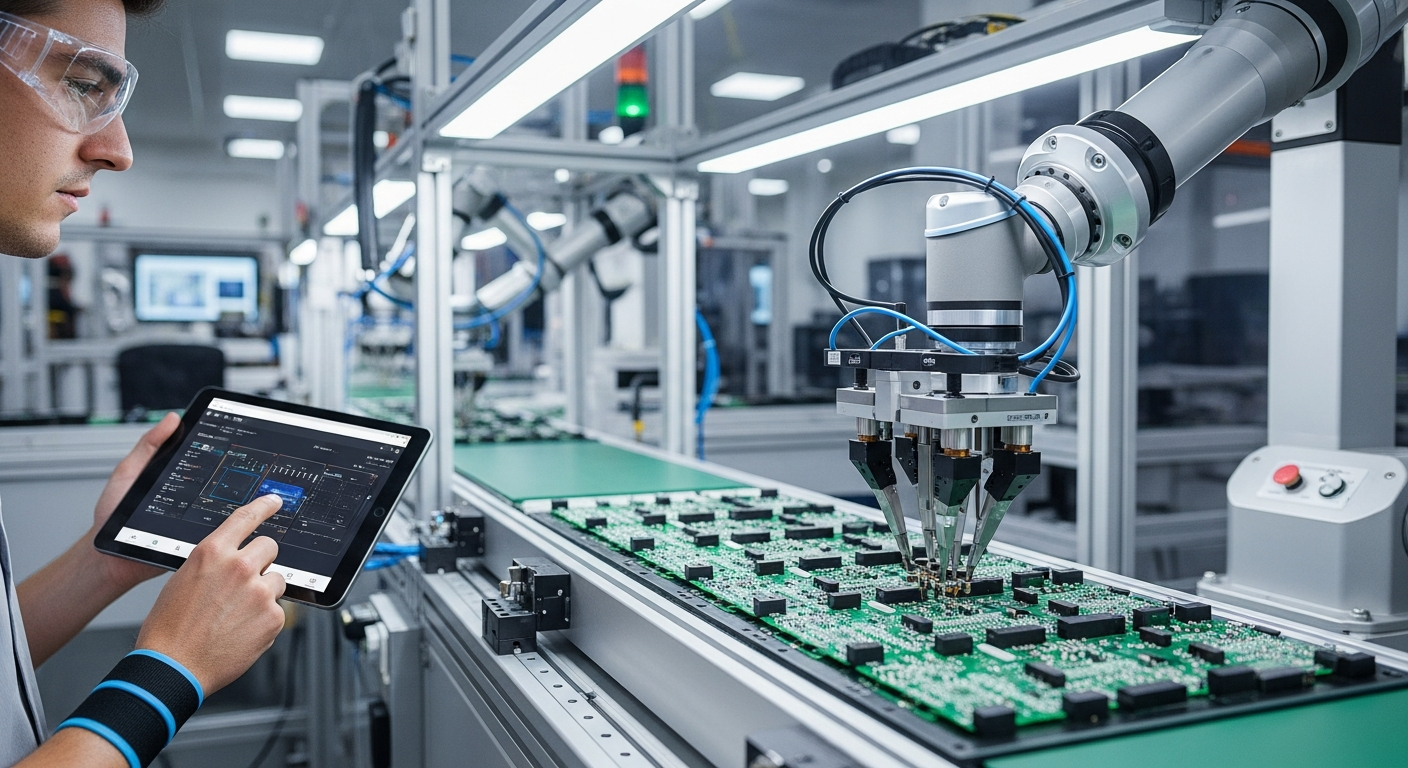

How is Automation Reshaping Manufacturing and Production?

Automation stands at the forefront of the manufacturing revolution, fundamentally altering how goods are produced. Advanced robotics, collaborative robots (cobots), and autonomous guided vehicles (AGVs) are increasingly integrated into production lines, performing tasks ranging from assembly and welding to material handling. This shift not only boosts production speed and consistency but also significantly improves efficiency by reducing human error and enabling continuous operation. The adoption of automation technology allows enterprises to reallocate human capital to more complex problem-solving, innovation, and quality control, thereby enhancing overall workforce engagement and output.

Furthermore, the convergence of automation with artificial intelligence (AI) and machine learning (ML) is giving rise to intelligent manufacturing systems. These systems can predict equipment failures, optimize production schedules, and even self-correct processes in real-time, leading to substantial gains in operational efficiency and a reduction in waste. The drive towards greater automation is a strategic imperative for businesses seeking to thrive in an increasingly competitive global market.

What are the Emerging Trends in Supply Chain and Logistics?

Modern supply chains are becoming more complex and interconnected, necessitating innovative approaches to logistics and management. Digital transformation is enabling greater visibility and responsiveness across the entire supply chain, from raw material sourcing to final product delivery. Technologies like blockchain are being explored to create transparent and immutable records of transactions and movements, enhancing trust and traceability. This can be particularly valuable for ensuring ethical sourcing and compliance with regulatory standards across global operations.

The integration of the Internet of Things (IoT) devices allows for real-time tracking of goods, monitoring environmental conditions during transit, and optimizing delivery routes. Predictive analytics, powered by vast datasets, helps anticipate demand fluctuations, potential disruptions, and optimizes inventory levels, reducing carrying costs and improving service levels. These advancements are crucial for building resilient supply chains that can withstand economic volatility and unforeseen global challenges, ensuring consistent commerce and market supply.

How Does Workforce Development Adapt to New Manufacturing Technologies?

The rapid adoption of advanced manufacturing technologies necessitates a significant evolution in workforce skills and development. As automation takes over repetitive tasks, the demand for roles requiring critical thinking, data analysis, programming, and human-machine collaboration is growing. Enterprises are investing in upskilling and reskilling programs to equip their existing workforce with the competencies needed to operate and maintain sophisticated systems, interpret data, and manage automated processes.

Educational institutions and industry partnerships are playing a vital role in developing curricula that align with future industry needs. This includes training in areas such as industrial cybersecurity, advanced robotics programming, and data science. Fostering a culture of continuous learning and adaptability is paramount for employees to thrive alongside technological innovation, ensuring that human ingenuity remains a core asset in the evolving production landscape. Investing in people is as crucial as investing in technology for sustainable growth and development.

What Role Does Sustainability Play in Future Manufacturing Strategy?

Sustainability is no longer an optional add-on but a core strategic imperative for modern manufacturing. Consumers, regulators, and investors are increasingly demanding environmentally responsible production practices. Technology offers powerful tools to achieve sustainability goals. Advanced materials science is leading to the development of lighter, more durable, and recyclable materials, reducing resource consumption and waste. Additive manufacturing (3D printing) minimizes material waste by building products layer by layer, only using what is necessary.

Energy management systems, powered by AI and IoT, optimize energy consumption within factories, reducing carbon footprints. Furthermore, circular economy principles are gaining traction, where products are designed for longevity, repairability, and eventual recycling, minimizing environmental impact throughout their lifecycle. Embracing these sustainable practices not only benefits the planet but also enhances brand reputation, attracts eco-conscious consumers, and can lead to significant long-term cost savings and operational efficiency.

How do Global Economic Shifts Influence Manufacturing Growth?

Global economic shifts, including trade policies, geopolitical dynamics, and fluctuating market demands, profoundly influence manufacturing growth and strategy. Manufacturers must adopt agile operations and a diversified global footprint to mitigate risks and capitalize on emerging opportunities. The push towards reshoring or nearshoring production, driven by supply chain vulnerabilities exposed during recent global events, is a notable trend impacting logistics and regional economies.

Digital platforms and advanced analytics provide businesses with deeper insights into market trends and consumer behavior across different regions, enabling more informed strategic decisions. This allows for tailored production and distribution strategies that cater to local preferences while maintaining global standards. The ability to quickly adapt production volumes and product offerings in response to economic indicators and market shifts is key to maintaining competitiveness and fostering robust enterprise growth in an interconnected world.