Navigating Market Shifts in Global Production Systems

The global landscape for production systems is in a constant state of flux, shaped by technological advancements, evolving economic conditions, and shifting geopolitical dynamics. Businesses worldwide are continuously seeking effective strategies to adapt to these changes, maintain operational resilience, and foster sustainable growth. Understanding the multifaceted nature of these market shifts is crucial for enterprises aiming to optimize their manufacturing processes, enhance supply chain efficiency, and leverage innovation for future success in a highly interconnected global economy.

The contemporary global economy presents a complex environment for production systems, characterized by rapid technological evolution and dynamic market forces. Enterprises engaged in manufacturing and trade must continuously evaluate their strategies to remain competitive and responsive. This involves a deep understanding of how global economic trends, consumer demands, and geopolitical developments influence operational paradigms and long-term planning.

Understanding Global Manufacturing Trends

Global manufacturing is experiencing significant transformations, moving beyond traditional models. Shifts towards regionalization, driven by geopolitical considerations and the pursuit of supply chain resilience, are reshaping where and how goods are produced. This impacts international trade flows and necessitates new approaches to global operations. Companies are increasingly diversifying their manufacturing footprints to mitigate risks associated with over-reliance on single regions, fostering a more distributed and adaptable production network.

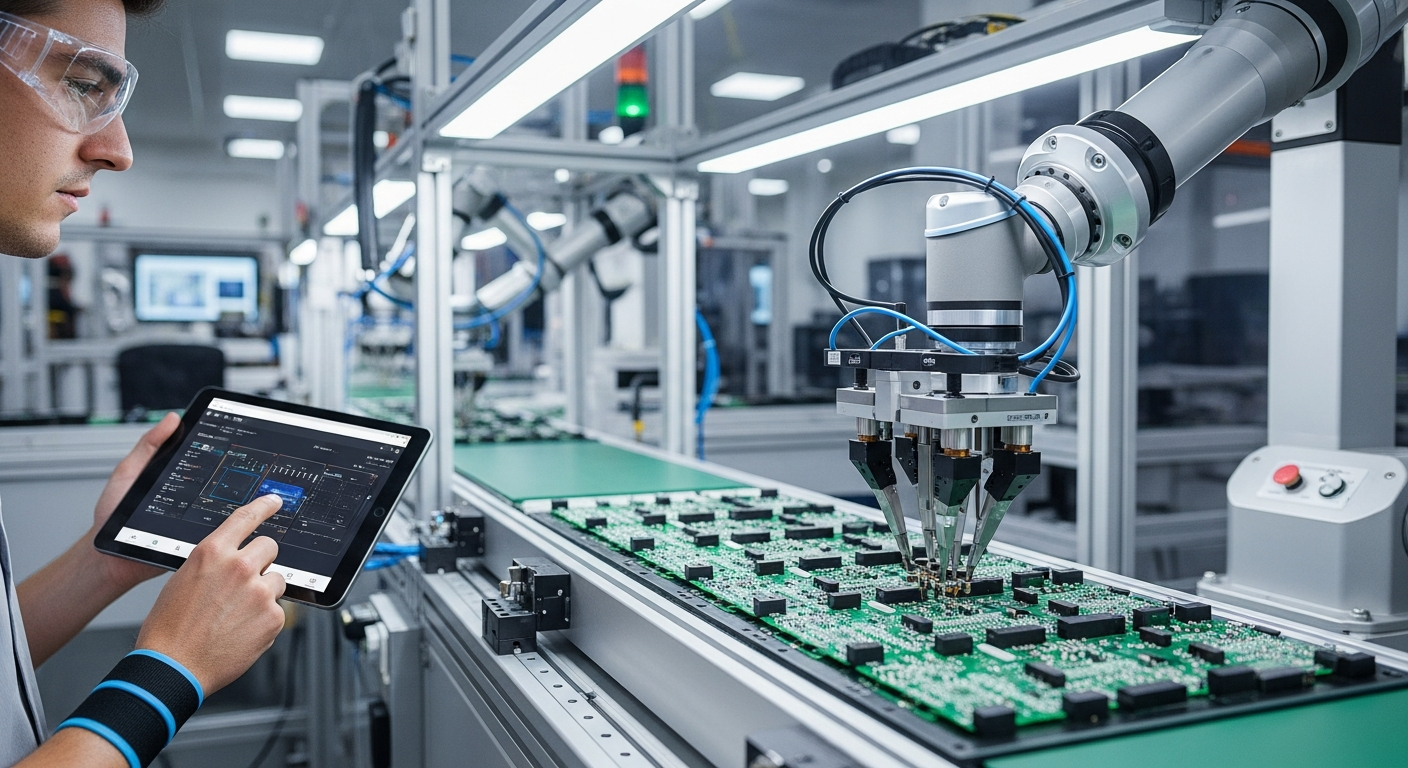

Leveraging Technology and Automation in Production

Innovation and technology are central to navigating market shifts. The adoption of advanced technologies such as artificial intelligence, the Internet of Things (IoT), and robotics is driving automation across production lines. Digitalization efforts are transforming traditional manufacturing processes into smart factories, enhancing productivity, and enabling more precise control over operations. This integration allows for real-time data analysis, predictive maintenance, and greater flexibility in responding to market demands, which are critical for enterprise growth.

Optimizing Global Logistics and Supply Chain Efficiency

Efficient logistics and robust supply chain management are paramount in a globalized production system. Market shifts often highlight vulnerabilities in existing supply networks, prompting businesses to focus on creating more resilient and transparent supply chains. Strategies include diversifying suppliers, implementing advanced tracking systems, and utilizing analytics to predict potential disruptions. The goal is to ensure a continuous and efficient flow of materials and products from source to consumer, even amidst economic volatility or unforeseen global events.

Strategic Adaptation for Market Shifts and Sustainability

Developing a proactive strategy is essential for enterprises to adapt to market shifts effectively. This involves continuous market analysis, scenario planning, and fostering an agile organizational culture capable of rapid decision-making. Furthermore, sustainability has emerged as a critical strategic imperative. Consumers and regulators increasingly demand environmentally responsible production practices. Integrating sustainable operations, from resource efficiency in manufacturing to ethical sourcing in the supply chain, not only meets these expectations but can also drive innovation and long-term business development.

Enhancing Productivity and Growth Through Data Analytics

Data analytics plays a pivotal role in enhancing productivity and driving growth within global production systems. By collecting and analyzing vast amounts of operational data, companies can gain insights into production bottlenecks, predict equipment failures, and optimize resource allocation. These insights inform strategic decisions, leading to improved efficiency, reduced waste, and better overall operational performance. The judicious use of analytics allows businesses to identify new market opportunities and tailor their offerings, fostering sustained growth and competitive advantage in a dynamic economy.

Navigating the complexities of market shifts in global production systems requires a multi-faceted approach. Enterprises must remain adaptable, embrace technological advancements, optimize their logistics, and embed sustainability into their core strategies. Continuous analysis of global economic indicators and proactive innovation are key to maintaining resilience and achieving long-term success in an ever-evolving industrial landscape.