Optimizing Production Processes for Efficiency Gains

In today's dynamic business environment, industries worldwide are continually seeking methods to enhance their operational efficiency. Optimizing production processes is a fundamental strategy for achieving sustainable growth and maintaining a competitive edge. This involves a comprehensive review of existing workflows, identifying bottlenecks, and implementing targeted improvements to streamline operations, reduce waste, and improve overall output quality.

Understanding Production Process Optimization

Production process optimization is a systematic approach focused on improving the effectiveness and efficiency of how goods or services are created. It involves analyzing every stage of the manufacturing or service delivery pipeline, from raw material procurement to final product distribution. The goal is to maximize output while minimizing resource consumption, including time, labor, and materials. This continuous improvement philosophy is crucial for enterprise success, allowing businesses to adapt to market demands and achieve growth.

Key Strategies for Efficiency and Growth

Implementing effective strategies is central to achieving efficiency gains in production. Lean manufacturing principles, for instance, focus on eliminating waste in all its forms, such as overproduction, waiting, unnecessary transport, over-processing, excess inventory, unnecessary motion, and defects. Six Sigma methodologies aim to reduce process variation and improve quality, leading to fewer defects and higher customer satisfaction. Both approaches contribute significantly to cost reduction and enhanced operations, fostering sustainable growth for the industry.

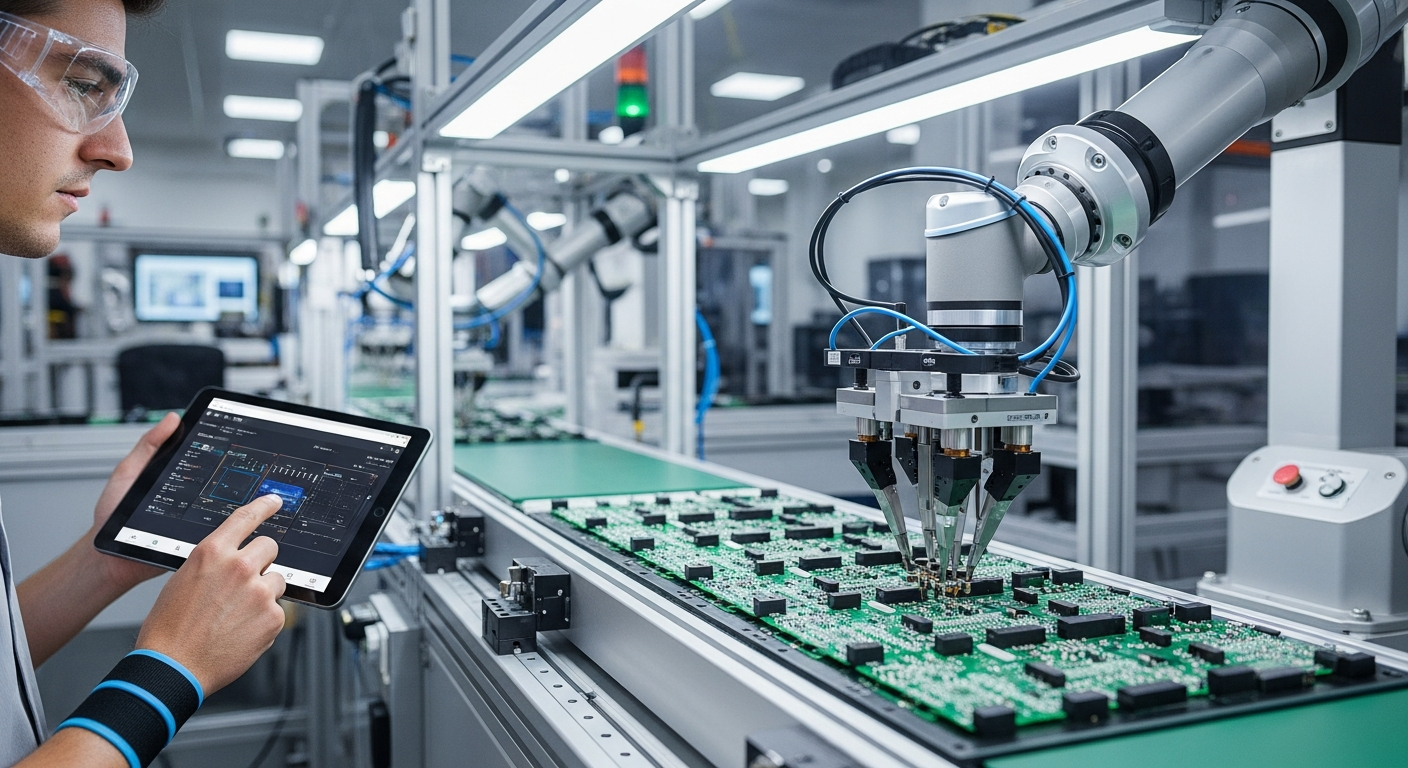

The Role of Technology and Automation in Manufacturing

Technology plays a transformative role in modern production process optimization. Automation, through robotics and advanced machinery, can perform repetitive tasks with greater speed and precision than human labor, reducing errors and increasing throughput. Industrial Internet of Things (IIoT) devices provide real-time data on machine performance, allowing for predictive maintenance and proactive problem-solving. Artificial intelligence and machine learning algorithms can analyze vast datasets to identify patterns, predict future outcomes, and recommend optimal operational adjustments, further boosting efficiency across the manufacturing operations.

Enhancing Supply Chain and Logistics Operations

A robust supply chain is integral to efficient production. Optimizing logistics involves streamlining the movement of materials and products, from sourcing to delivery. This includes strategic warehouse management, efficient transportation routes, and effective inventory control to prevent stockouts or overstocking. Digital tools for supply chain management (SCM) can provide end-to-end visibility, enabling better coordination with suppliers and distributors. Improved logistics directly impact production schedules and costs, contributing to overall commerce efficiency and global competitiveness.

Workforce Development and Management in Industry

The workforce is a critical component of any production system. Investing in development and effective management practices can significantly impact efficiency. This includes comprehensive training programs to equip employees with the skills needed to operate new technology and embrace optimized processes. Fostering a culture of continuous improvement, where employees are encouraged to identify and suggest improvements, can lead to valuable innovation. Empowering the workforce through clear communication and involvement in strategy development ensures that human capital is leveraged effectively for industry advancement and economy contribution.

| Provider Name | Services Offered | Key Features/Benefits |

|---|---|---|

| Accenture | Operations Consulting, Digital Transformation | Global reach, industry-specific expertise, technology integration |

| McKinsey & Company | Manufacturing & Supply Chain Optimization, Lean Transformation | Strategic management consulting, data-driven insights, change management |

| Deloitte Consulting | Production System Design, Performance Improvement | Risk management, supply chain analytics, technology advisory |

| Boston Consulting Group (BCG) | Smart Manufacturing, Operations Strategy |

Digital innovation, advanced analytics, sustainable operations |

| Siemens Digital Industries | Industrial Automation, Manufacturing Software |

Integrated hardware and software solutions, predictive maintenance, IoT platforms |

| SAP | Enterprise Resource Planning (ERP), Supply Chain Management (SCM) | Comprehensive business process integration, real-time data, global operations support |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Continuous Innovation and Global Strategy

Sustained efficiency in production processes requires a commitment to continuous innovation and a forward-looking global strategy. Businesses must regularly assess new technology trends, market shifts, and competitive landscapes to identify opportunities for further optimization. Embracing a strategy that prioritizes adaptability and proactive problem-solving ensures that operations remain agile and responsive. This ongoing development is not merely about cost reduction but also about enhancing product quality, speeding up time-to-market, and ultimately strengthening a company’s position within the global economy and its respective industry.

Optimizing production processes is an ongoing journey that requires dedication to continuous improvement, strategic technology adoption, and effective workforce management. By systematically addressing each element of the production lifecycle, businesses can achieve significant efficiency gains, foster innovation, and secure a competitive advantage in the global market.