Supply Chain Resilience in a Global Economy

Modern enterprises face unprecedented challenges in maintaining stable operations across international markets. Supply chain disruptions, shifting trade policies, and evolving consumer demands require organizations to rethink traditional logistics and manufacturing approaches. Building resilience has become essential for businesses seeking to navigate economic uncertainty while maintaining productivity and growth. This article examines the strategies, technologies, and management practices that help organizations strengthen their supply chains and adapt to a rapidly changing global landscape.

Supply chain resilience refers to an organization’s ability to anticipate, prepare for, respond to, and recover from disruptions while maintaining continuous operations. In today’s interconnected global economy, businesses depend on complex networks spanning multiple countries, suppliers, and transportation systems. Events such as natural disasters, geopolitical tensions, pandemics, and economic shifts can quickly cascade through these networks, affecting production schedules, inventory levels, and customer satisfaction. Organizations that invest in resilience strategies position themselves to weather disruptions more effectively than competitors who rely solely on efficiency-focused models.

How Do Enterprises Build Stronger Supply Networks?

Enterprises strengthen their supply networks through diversification, visibility, and strategic partnerships. Diversification involves sourcing materials and components from multiple suppliers across different geographic regions, reducing dependence on single sources. Visibility requires implementing systems that provide real-time data on inventory levels, shipment locations, and supplier performance. Strategic partnerships with logistics providers, manufacturers, and technology vendors create collaborative relationships that enable faster problem-solving during disruptions. Many organizations also maintain safety stock for critical components and develop contingency plans that outline alternative suppliers and transportation routes. Regular risk assessments help identify vulnerabilities before they become critical issues.

What Role Does Industry Innovation Play in Logistics?

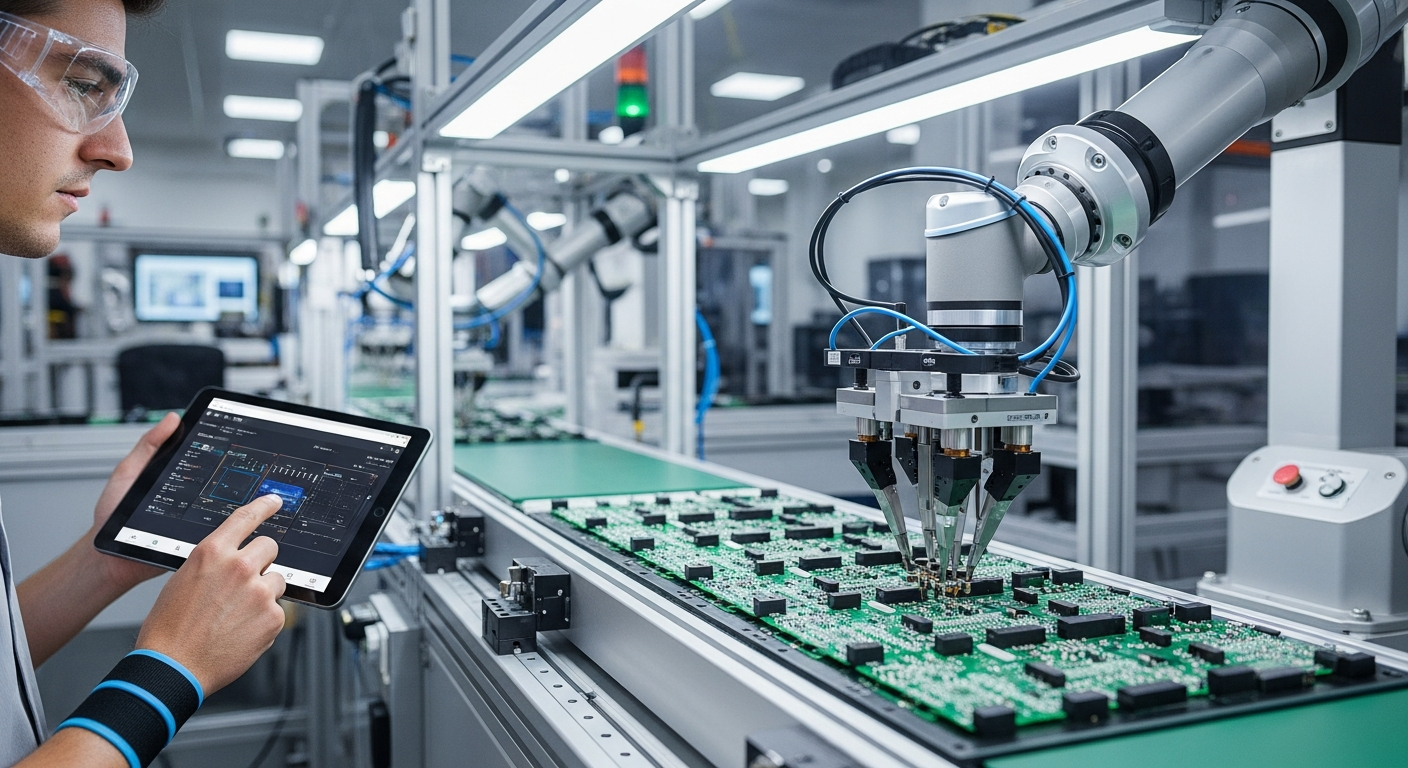

Innovation transforms logistics operations through advanced technologies and new operational models. Automation technologies such as robotic process automation, autonomous vehicles, and warehouse robotics reduce manual labor requirements while increasing speed and accuracy. Digitalization enables organizations to capture and analyze vast amounts of data from sensors, tracking systems, and enterprise software platforms. These insights support better decision-making around routing, inventory placement, and demand forecasting. Innovations in packaging materials reduce waste and transportation costs, while new delivery models such as micro-fulfillment centers bring inventory closer to end customers. Blockchain technology provides transparent, tamper-proof records of transactions and movements throughout the supply chain, enhancing trust and traceability.

How Does Manufacturing Adapt to Changing Markets?

Manufacturing operations adapt through flexible production systems, workforce development, and sustainability initiatives. Flexible manufacturing systems allow facilities to quickly reconfigure production lines for different products, responding to changing demand without major capital investments. Workforce development programs ensure employees possess skills needed to operate advanced equipment and adapt to new processes. Sustainability initiatives reduce environmental impact through energy-efficient equipment, waste reduction programs, and circular economy principles that reuse materials. Many manufacturers adopt lean principles to eliminate waste and improve efficiency, while others implement agile methodologies that emphasize rapid iteration and customer feedback. Regional manufacturing strategies balance cost considerations with proximity to key markets and reduced transportation complexity.

What Management Strategies Support Operational Efficiency?

Effective management strategies combine data-driven decision-making with organizational agility. Operations managers use key performance indicators to monitor productivity, quality, delivery performance, and cost metrics across the supply chain. Scenario planning exercises prepare teams for potential disruptions by walking through response procedures and identifying resource requirements. Cross-functional collaboration breaks down silos between departments such as procurement, production, sales, and logistics, enabling coordinated responses to challenges. Investment in workforce training ensures employees understand their roles in maintaining resilience and can execute contingency plans effectively. Regular supplier audits and performance reviews maintain quality standards and identify potential risks before they impact operations. Technology platforms that integrate data from multiple systems provide unified visibility and support coordinated decision-making.

How Do Organizations Balance Growth and Sustainability?

Organizations balance growth objectives with sustainability commitments through integrated strategies that view environmental responsibility as a competitive advantage rather than a constraint. Sustainable practices often reduce costs through improved energy efficiency, waste reduction, and optimized transportation routes. Companies set measurable sustainability targets for carbon emissions, water usage, and waste generation, then track progress through regular reporting. Circular economy models that emphasize product longevity, reuse, and recycling create new revenue streams while reducing environmental impact. Partnerships with suppliers who share sustainability commitments extend these practices throughout the supply chain. Consumer preferences increasingly favor environmentally responsible products, making sustainability a market differentiator that supports growth. Regulatory requirements in many jurisdictions mandate environmental reporting and set standards for emissions and waste, making sustainability integration essential for market access.

What Does Digitalization Mean for Commerce Strategy?

Digitalization fundamentally reshapes commerce strategy by enabling new business models, customer experiences, and operational capabilities. E-commerce platforms expand market reach beyond traditional geographic boundaries, while digital marketing tools provide precise targeting and measurable results. Customer relationship management systems capture interaction data that informs product development and service improvements. Digital twins create virtual replicas of physical assets, allowing organizations to simulate scenarios and optimize performance without disrupting actual operations. Artificial intelligence and machine learning algorithms analyze patterns in customer behavior, demand fluctuations, and operational performance to generate actionable insights. Cloud computing provides scalable infrastructure that supports rapid growth without major capital expenditures. Organizations that successfully integrate digital technologies throughout their operations gain advantages in speed, flexibility, and customer responsiveness that translate into competitive positioning in global markets.

Building supply chain resilience requires ongoing commitment to innovation, workforce development, and strategic planning. Organizations that view resilience as a core capability rather than a cost center position themselves for sustainable success in an increasingly complex global economy. The integration of advanced technologies, sustainable practices, and flexible operational models creates supply chains capable of adapting to whatever challenges emerge in the years ahead.